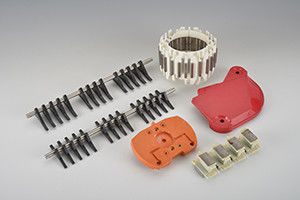

120 Ton Vertical Rotary Table Injection Molding Machine For Home Appliance Accessories

TAIFU low-station vertical rotary table injection molding machine adopts an ergonomic work surface to make operation more convenient and safer. The minimum diameter of the turntable is 810mm and the maximum diameter is 2300mm.

The operation of the 120-ton vertical rotary table injection molding machine involves several steps. First, the molten material is prepared by melting the appropriate material, such as plastic or rubber. The mold is loaded onto the rotary table, and the clamping system secures it in place. The injection unit injects the molten material into the mold cavity as the rotary table rotates, allowing multiple cavities to be filled. Once the material has cooled and solidified within the mold, the mold opens, and the finished home appliance accessories are ejected.

The machine is equipped with a high-performance control system to provide a strong guarantee for high-quality injection molding accuracy and stability. Because of its unique rotatable disc design, the vertical turntable injection molding machine can be used with expanded automation equipment to achieve high-quality and efficient automated production of products with complex shapes and special processes. It is now widely used in auto parts and new energy industry.

1.Specification:

| |

UNIT |

TFW4-85R2 |

TFW4-120R2 |

TFW4-160R2 |

| Injection Unit |

Screw stroke |

mm |

140 |

160 |

200 |

| Screw Diameter |

mm |

32 |

36 |

40 |

36 |

40 |

45 |

45 |

50 |

55 |

| Theoretical Injection Volume |

cm3 |

113 |

143 |

176 |

163 |

201 |

254 |

318 |

393 |

475 |

| Injection Weight(PS) |

g |

105 |

133 |

164 |

151 |

187 |

237 |

296 |

365 |

442 |

| oz |

3.69 |

4.67 |

5.77 |

5.34 |

6.60 |

8.35 |

10.43 |

12.88 |

15.59 |

| Max.Injection Pressure |

Mpa |

228 |

180 |

146 |

222 |

180 |

142 |

218 |

177 |

146 |

| kgf/cm2 |

2331 |

1842 |

1492 |

2269 |

1838 |

1452 |

2226 |

1803 |

1490 |

| Injection Rate |

cm3/s |

100 |

126 |

156 |

128 |

158 |

200 |

167 |

206 |

249 |

| Max Injection Speed |

mm/s |

124 |

126 |

105 |

| Screw Speed Rotation |

r.p.m |

10~280 |

10~280 |

10~280 |

| Positioning ring diameter |

mm |

120 |

120 |

120 |

| Nozzle Out From Platens |

mm |

≥45 |

≥45 |

≥45 |

| Clamping Unit |

Clamping Force |

KN(ton) |

833(85) |

1176(120) |

1568(160) |

| Clamping Stroke |

mm |

280 |

300 |

350 |

| Min.Mold Thickness |

mm |

230(310) |

280(380) |

300(400) |

| Max.Opening |

mm |

510(590) |

580(680) |

650(750) |

| (L*W)Max.Mould Size |

mm |

360*360/450*320 |

420*420/560*360 |

520*520/700*450 |

| Number of turntable stations |

mm |

2 |

2 |

2 |

| (D) Rotary Table Size |

mm |

φ1010 |

φ1200 |

φ1400 |

| Quality of Ejector |

pcs |

3 |

5 |

5 |

| Top bar spacing |

mm |

80 |

80 |

100 |

| Ejector Distance |

mm |

100 |

100 |

110 |

| Ejector Force |

KN(ton) |

45(4.6) |

45(4.6) |

45(4.6) |

| Others |

System Pressure |

Mpa(kgf/cm2) |

13.7(140) |

13.7(140) |

13.7(140) |

| Oil Tank Capacity |

L |

350 |

430 |

500 |

| Electric Power |

KW |

15+2.2 |

18+2.2 |

22+2.2 |

| Heater Power |

KW |

7.0 |

10.7 |

13.7 |

| Machine Dimensions |

L*W*H |

m |

2.5*1.9*2.5 |

2.6*2.0*2.9 |

2.9*2.2*3.3 |

| Cooling water capacity |

L/min |

40 |

50 |

50 |

| Work Table Height |

mm |

780+(70) |

820+(70) |

915+(80) |

| Machine Weight |

ton |

6.5 |

9.5 |

12.8 |

2. Features:

- The machine is designed with a low work table, which provides easy access for operators to load molds, perform maintenance tasks, and monitor the injection molding process. The low work table height ensures convenience and ergonomics during operation.

- The turntable design adopts MLT technology to improve the durability of the turntable. The turntable control adopts DCPC digital closed-loop technology control. The turntable movement is smooth and impact-free, and the positioning is accurate.

- High efficiency

3. Machine Pictures:

4. Applications:

5. Why choose us?

1. Best product quality and most competitive price.

2. Experienced technical personnel in production.

3. Customized design and production.

4. Excellent pre-sales and after-sales services.

6. FAQ:

Q: Are you a trading company or manufacturer?

A: We are a factory located in Dongguan city-the largest industrial manufacturing area in China. All the machines are manufactured by our own employees in our own factory.

Q: Do you test all goods before delivery?

Yes, we have 100% testing before delivery

Q: How about your delivery time?

Generally speaking, it will take 20 to 45 days after receiving the advance payment. The specific delivery time depends on

Regarding your order and quantity.

Q: What are your payment terms?

T/T 30% deposite,70%before departure.

Q: Packaging and shipping?

The spool is plastic-covered inside and cartoned outside. Or according to your request.

If you are interested in our machines, please do not hesitate to CONTACT US!

Contact Details

Dongguan Taifu Machinery Co., Ltd

Contact Person: Daisy Hurry

WhatsApp: 8615274713539

Email: daisy.taifu5151@gmail.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!