160 Ton BMC Vertical Clamping Horizontal Injection Molding Machine Servo Motor Injection Molding Machine

Taifu company product introduction.pdf

TAIFU vertical horizontal injection BMC molding machine is a special type of injection molding machine with vertical mold clamping and horizontal injection working methods. It is suitable for injection molding of BMC rubber. The mold is closed in the vertical direction. This working method makes the mold structure simple, easy to maintain precision, and easier to embed. The BMC material is injected from a horizontal direction, making the injection molding process more stable and efficient.

We can customize and develop according to the actual needs of customers and provide the most precise, efficient and economical personalized combination solutions.

1. Sepcifications:

| |

UNIT |

H120S-2M-BMC |

H160S-2M-BMC |

H220S-2M-BMC |

| Injection Unit |

Screw Diameter |

mm |

Φ85 |

Φ100 |

Φ100 |

| Theoretical Injection Volume |

cm3 |

1500 |

2000 |

3000 |

| Max.Injection Pressure |

Mpa(kgf/cm2) |

63(639) |

104(1060) |

68(700) |

| Injection Rate |

cm3/s |

207 |

230 |

305 |

| Injection Speed |

mm/s |

130 |

129 |

130 |

| Barrel capacity |

L |

35 |

45 |

45 |

| Clamping Unit |

Clamping Force |

KN(tf) |

1176(120) |

1624(160) |

2213(220) |

| Clamping Stroke |

mm |

400 |

400 |

400 |

| Open Force |

kN(tf) |

130(13) |

130(13) |

130(13) |

| Min.Mold Thickness |

mm |

350 |

350 |

350 |

| Max.Opening |

mm |

750 |

750 |

750 |

| (L*W)Distance Between Tie Bars |

mm |

525*375 |

760*380 |

760*380 |

| (L*W)Max.Mould Size |

mm |

500*580 |

560*670 |

560*670 |

| (L*W)尺寸Platen Size |

mm |

500*580 |

560*670 |

560*670 |

| Ejector Distance |

mm |

100 |

120 |

120 |

| Ejector Force |

KN(tf) |

87.7(8.6) |

95(9.3) |

106(10.4) |

| Others |

System Pressure |

Mpa(kgf/cm2) |

17.2(175) |

18.4(188) |

20.6(210) |

| Oil Tank Capacity |

L |

300 |

300 |

300 |

| Electric Power |

KW(HP) |

26 |

26 |

34 |

| Machine Size |

L*W*H |

m |

3385*126*2840 |

3385*1260*2840 |

3385*1260*2840 |

| Machine Weight |

tf |

19 |

20 |

22 |

2. Features:

- The unique water transport design ensures effective heat dissipation when in contact with the hot mold and prevents the rubber from vulcanizing in the nozzle flow channel.

- The pneumatic sealing system is used, which is synchronized with the injection signal of the injection molding machine, and can effectively and quickly complete the sealing action simultaneously.

- Unique precision sealing needle design, nozzle hole and sealing needle seam can achieve no flash and no glue overflow.

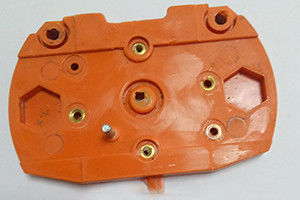

3. Machine Pictures:

4. Applications:

5. FAQ:

Q: What is BMC material?

A: BMC is a kind of thermosetting plastic, because it has good fluidity, it is very suitable for injection molding. BMC, also known as "bulk molding compound", is an unusual type of plastic pellets.

Q: What is the difference between thermoplastic and injection molding?

A: In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. This process cures the part so it can never be melted again. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part.

Q: Are you a trading company or manufacturer?

A: We are a factory located in Dongguan city-the largest industrial manufacturing area in China. All the machines are manufactured by our own employees in our own factory.

Q: How long is your delivery time?

A: Small machines are in stock. Generally, the delivery time of standard machines is 7~35 working days. For customized machines, it will be 40~60 working days.

Q: How long is the warranty time?

A: 1 year warranty for all the machines. We provide free parts for any not man-made damages and quality problems. Our technical support will accompany with you during the machines' lifetime. If machines are operated properly, it can service more than 20 years.

Q: What are your terms of payment?

A: 30%TT in advance, 70% balance before shipment. or L/C at sight.

If you are interested in our machines, please do not hesitate to CONTACT US!

Contact Details

Dongguan Taifu Machinery Co., Ltd

Contact Person: Daisy Hurry

WhatsApp: 8615274713539

Email: daisy.taifu5151@gmail.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!